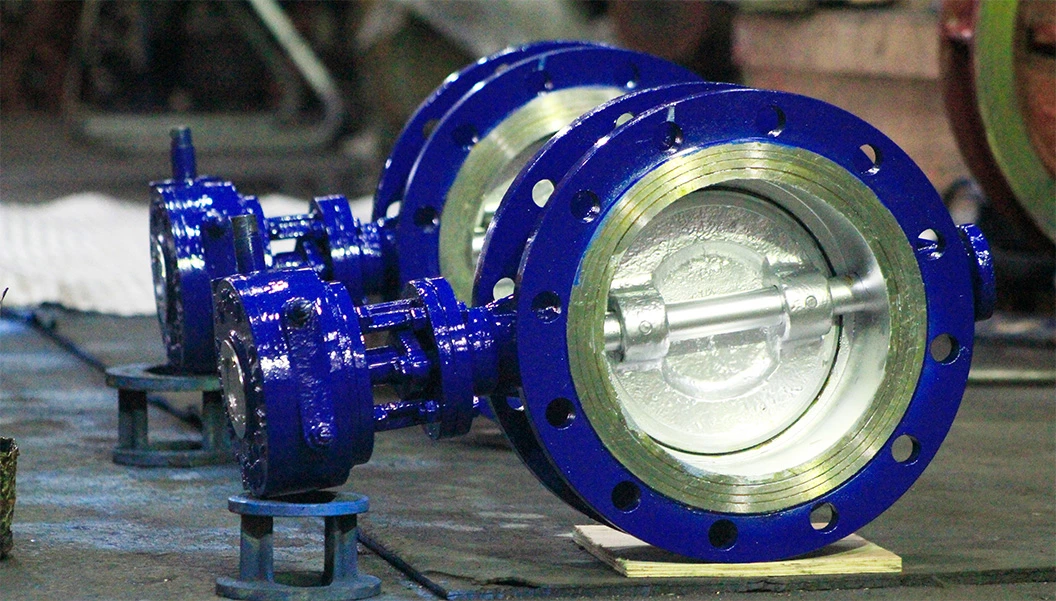

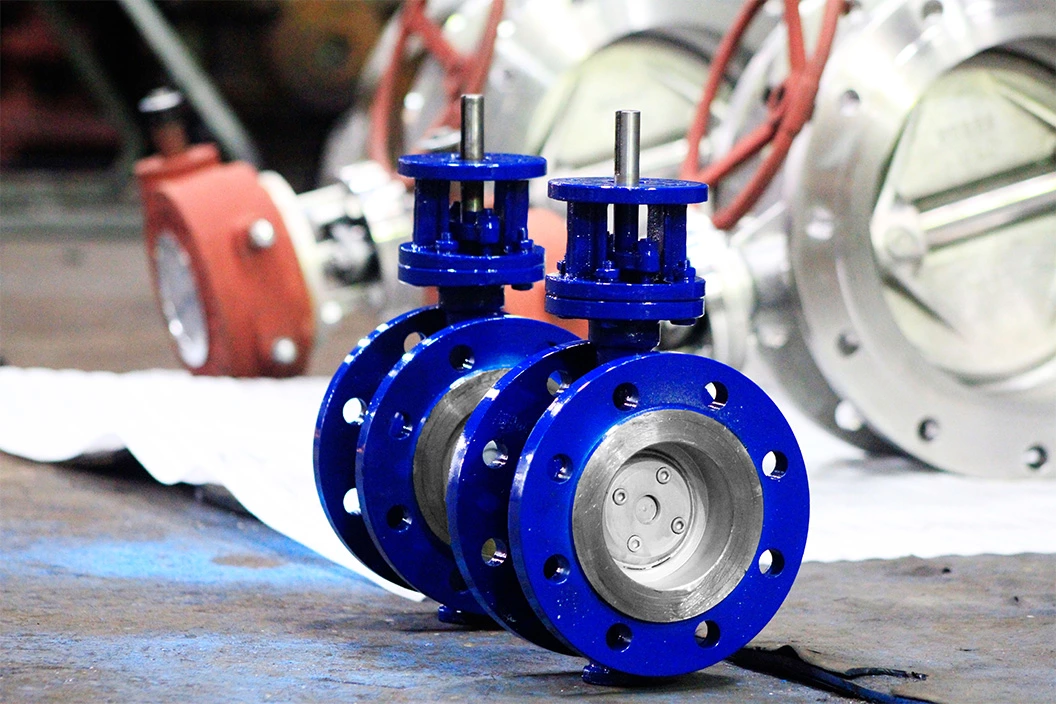

When Mactor valve triple-offset sealing butterfly valve in a fully open state, the butterfly plate sealing surface will be completely out of the valve seat sealing surface, and the butterfly plate seal and the valve body seal between the formation of double eccentric seal butterfly valve with the same gap,Due to the sealing surface angle offset will make the length and length of the radius of the butterfly plate to the size of the semicircle, the butterfly plate sealing surface rotation trajectory and the valve seat sealing surface to form an angle. When the disc is open, the sealing surface of the disc is immediately removed from the sealing surface of the valve seat. When the disc is closed, only in the closed moment, the butterfly plate sealing surface will contact and press the valve seat sealing surface, thus eliminating the mechanical seal of the seal and bruises. Three eccentric structure so that the closure of the butterfly plate when the seal between the two sealing surface seal pressure can be generated by the conventional valve seat elasticity coupled to the valve stem drive torque generated, not only clear the elastic material aging, failure. But also by the external drive torque changes to achieve its seal than the pressure of any adjustment, so that the sealing performance and service life has been greatly improved.

We use cookies to collect information about how you use this site. We use this information to make the website work as well as possible and improve our services.